Environment Solutions

Depuis 1993, la société AFHYMAT est fabricant d’équipements pour différents types de véhicule, véhicules industriels, du véhicule utilitaire 3.5T jusqu’au camion poids-lourd 32 Tonnes, de la petite à la grande série, en prônant la qualité, l’innovation et le service. Notre bureau d’étude d’experts pour vos solutions environnement, vous écoute, vous fait des propositions et réalise la conception et le développement CAO 3D-2D prototypages. A la pointe de la technologie, AFHYMAT assure une excellente productivité dans le respect des délais et des normes de fabrication aux normes françaises. Nous sommes le partenaire pour vous proposer des solutions environnement clés en main : Système de bâchage complet installé sur benne, Compacteurs à déchets, Camion broyeur d’archives, Bungalow aménagé à la demande, box pour la récupération des pneus usagés …

Du composant à la solution clé en main

Toutes nos belles aventures ont démarrées par une idée, un plan, puis cette idée a pris forme auprès du bureau d’étude, pour concevoir des pièces sur mesure. Le choix des composants est important, la qualité de la pièce fabriquée en France, cela impacte la fiabilité future lors de l’utilisation quotidienne.

Quels composants pour la construction d’une benne, d’un compacteur

Traitement des déchets

Le traitement de déchets grâce aux outils spécifiques tels les compacteurs déchets ou broyeurs de palette et les véhicules industriels dédiés comme les camions broyeurs traduisent l’engagement environnemental du fabricant français AFHYMAT.

Une recherche de solutions environnementales déjà engagée sur le terrain économique et écologique des carburants avec l’innovation exclusive du système de carburation Bimax et une offre de réalisations spécifiques en collecte ou traitement de déchets.

RIGIDCAP© : produit breveté AFHYMAT

Nous mettons à disposition notre bâchage innovant Rigidcap pour les constructeurs de benne et les clients utilisateurs. Notre produits est reconnu est utilisé par les plus grand dans le monde du recyclage, nous pouvons citer : Véolia, Paprec, Derichebourg ou encore Suez.

Notre système de bâchage se manipule du sol via une gaffe télescopique permettant l’ouverture dans les 2 sens ce qui en facilité l’implantation dans une déchetterie !

Le bâchage rend le caisson étanche représentant un argument majeur pour les marché du transport du carton ou encore des produits polluants comme les huiles de coupe. Rigidcap ne nécessite que très peu d’entretient et est conçu pour être utilisé dans les pires conditions d’utilisations.

Traitement de déchets : Le camion broyeur

AFHYMAT met à disposition des collectivités, des administrations, des établissements bancaires pour financer l’achat ou la location d’un camion broyeur.

Les documents à détruire sont déposés dans des conteneurs (poubelles) normalisés à 2 roues de 120L, qui sont vidés dans la trémie du broyeur à l’aide du lève conteneur, par un chauffeur-opérateur formé aux procédures strictes liées à la destruction de documents confidentiels et à l’utilisation particulière du MS10 de chez AFHYMAT (conçu par le bureau d’étude).

Le MS10 est constitué d’un châssis porteur motorisé, d’un caisson fixe muni d’un éjecteur, fermé par une porte arrière basculante contenant un système de compaction et un coffre contenant un broyeur industriel équipé d’un lève-conteneurs.

Pneus-box® le Conteneur pour pneus usagés

Nos produits sont spécialement conçu pour la récupération des pneumatiques usagés. AFHYMAT facilite la récolte de vos déchets et participe à votre effort pour l’environnement !

- Volume : 10 m3 pour une charge maximale de 1200Kg

- Jusqu’à 250 pneus

- Porte d’accès verrouillable par cadenas par homme à pied.

- Transportable par transpalette ou par charriot élévateur

- Ouverture par pince Kinshofer ( possibilité d’adapter d’autre type de pinces )

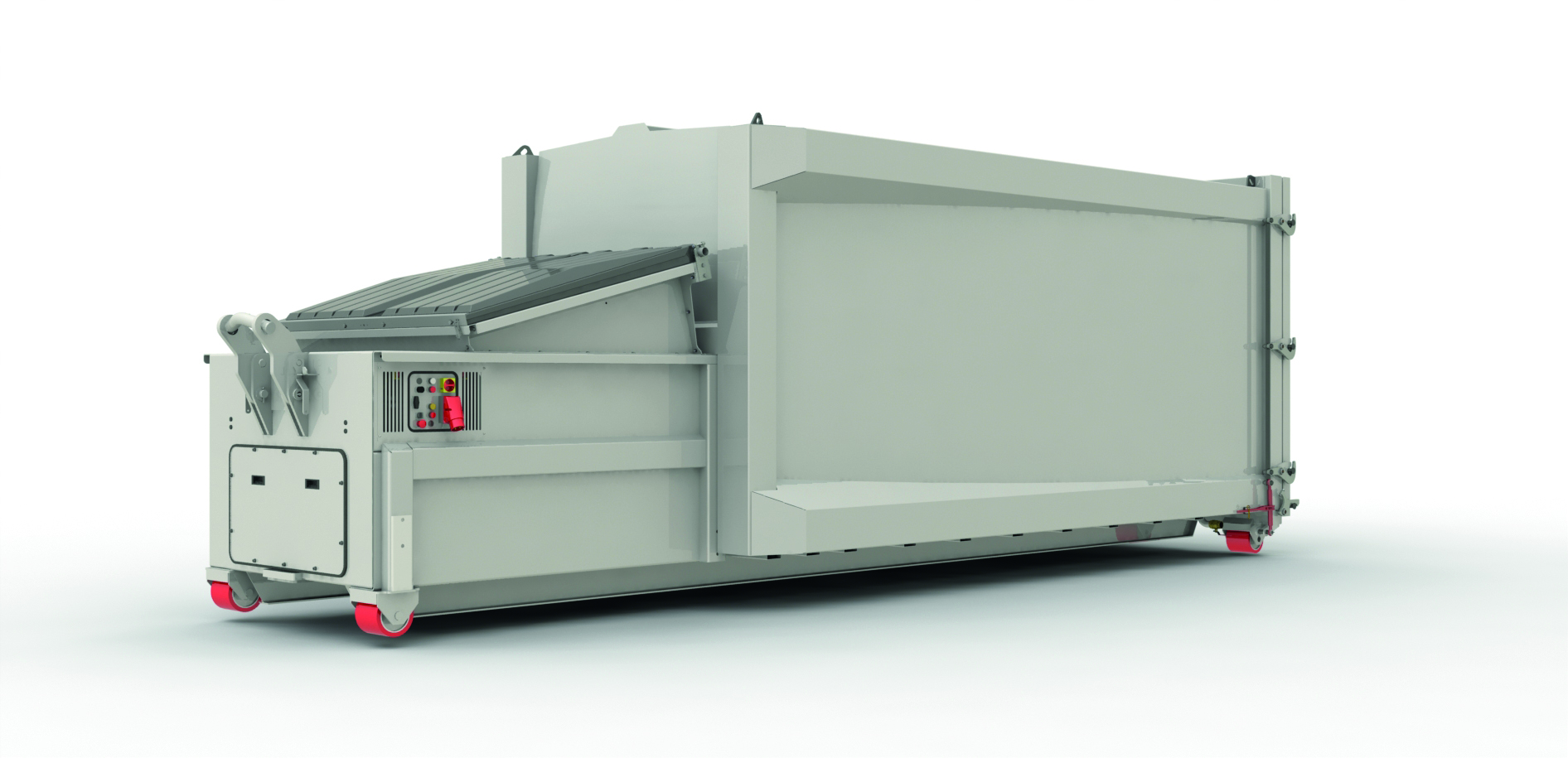

Compacteur monobloc standard de 10 à 25 m3

- Volume du caisson : 10 m3 à 25 m3

- Volume de la trémie de chargement : 1,5 m3

- Étanchéité renforcée

- 4 rouleaux

- Double préhension (avant et arrière)

- Crochet de préhension avant rabattable

- Avertissement 3/4 plein et 50% plein

- 2 vannes de vidange arrière droite/gauche

- Capot avec loquet de fermeture trémie

- Double panneau d’alimentation de chaque côté

- Télécommande à quai intégrée

- Force de compaction : 25000 daN

- Puissance moteur électrique : 7500 W

- Pression hydraulique maximale : 230 bars

- Durée d’un cycle : 45 secondes

- Lève-conteneur

Do you have a project, a question?

Our teams will support you in finding the solution you need.

Are you looking for a spare part?

More than 5000 references to order online in our shop.